KM5VI

Getting the Tower's Freshened Up & Ready to Go

Unloading Towers... the Easy Way!

US Tower is Still in Pretty Good Shape after 10 Years.

Triex W51 (right) gets a New Coat of Paint.

W51 Fulton Winch gets a Rebuild.

Preparing to Stretch Out the Triex LM470.

Thunderstorm Building Behind Me!

LM470 Looking Better.

The Hub City Gear Box (LM470) was in Poor Condition & Required All New Bearings.

New Bearings for the Lifting Cable.. and All New Cables Too.

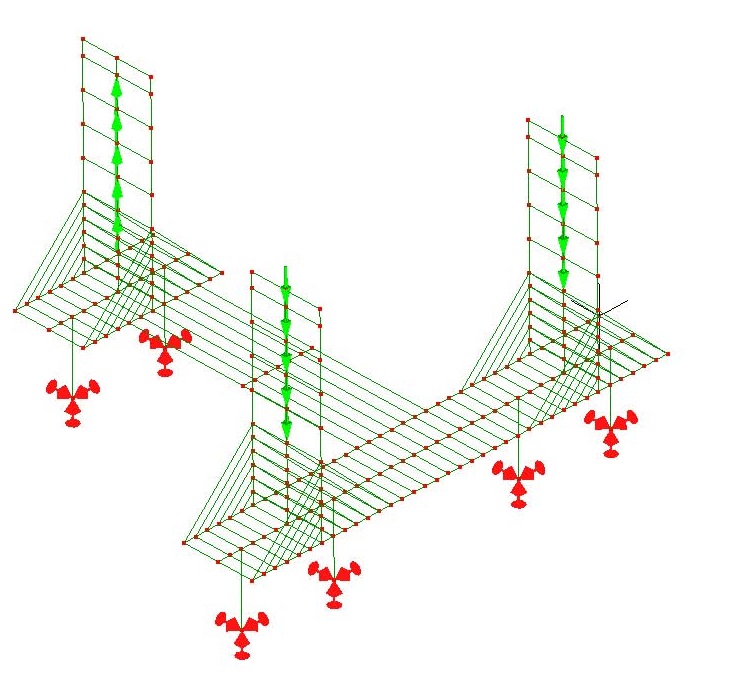

Finite Element Stress Analysis Model of New Base Plate for LM470

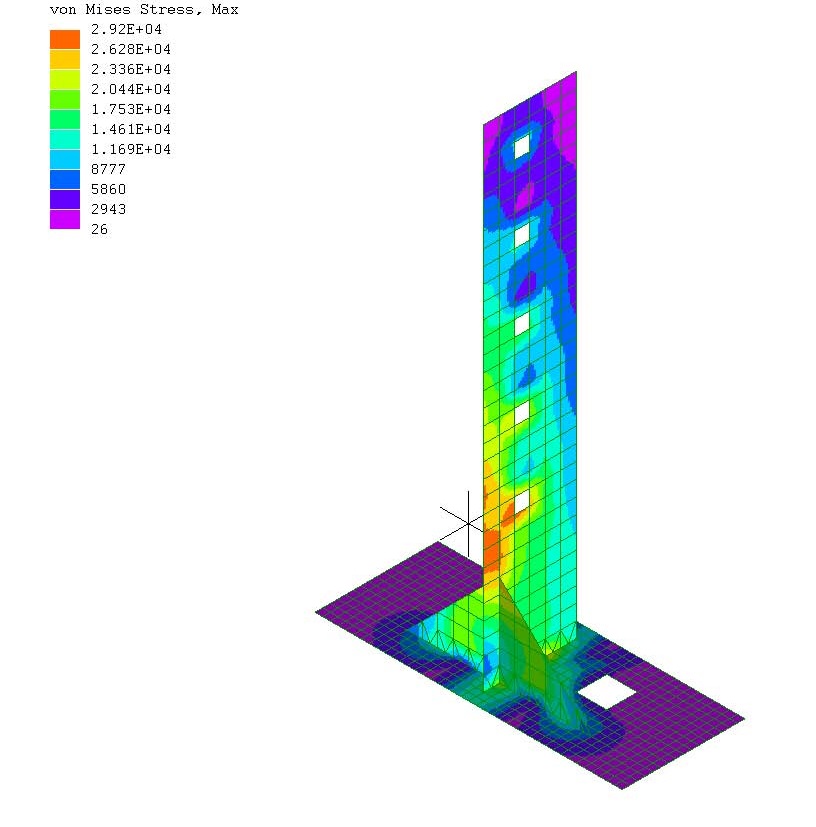

Stress Analysis of the Mounting Tab (Critical) after Some Reinforcing Revisions to the Design.

Peak Stress <30,000 psi (at Tower Failure Load), Material Strength ~40,000 psi (Mill Reports)

Fabricating Feet for Adjustable Tower Bases.

Closeup of Welding.

Fitting the Feet to the Tower Prior to Tacking in the Base Frame.

New Bases for the LM470 (left) & W51 (right) Ready for Galvanizing.

Back from the Galvanizing Shop.

Anchor Bolts Arrive.

Base Mock-up.

This Will Come in Useful for Installing the Underground Feedlines.